Research & Development

Because major investment demands performance that can be verified, at Keane Environmental we offer our customers the best possible products, making sure that they meet the necessary BS, CE and ISO quality standards.

Moreover, some of our suppliers have Research and Development centres which allow them to develop new products and continually improve the existing ones:

KAMPMANN

Kampmann’s in-house Research & Development Centre (FEC) is located at their headquarters in Lingen. It is one of the most modern facilities of its type in Europe and was designed to meet customers’ ever-changing demands:

- Functional demonstration and presentation of products,

- Tests simulating real operating conditions,

- Reliable technical data and proof of outputs,

- Continuous new developments and product enhancements.

The multifunctional design of the building with a floor area of approx. 1,200 m² houses an air flow laboratory, a multi-purpose laboratory and a sound chamber.

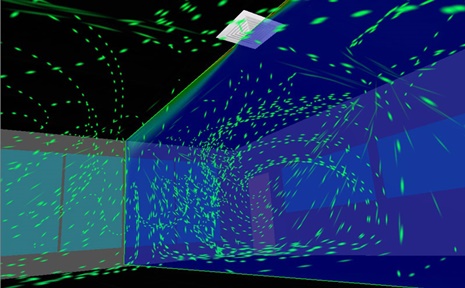

The air flow laboratory allows the simulation of a room’s climate. The walls, floor and ceiling of the air flow laboratory can be heated and cooled independently of each other and the air humidity can also be set as required, enabling the air and room conditions in planned buildings to be simulated precisely in order to supply detailed information about the effect of the heating, cooling or ventilation units used. This applies for performance data and also for air flows in the room or comfort analyses.

The main focus of the multi-purpose laboratory is to carry out highly accurate air volume measurements and thermodynamic tests on larger ventilation units. A test chamber is available for these measurements that can measure flow rates in the range of 28 m³/h to 10,000 m³/h at a maximum error of 0.5%.

GILBERTS

Gilbert’s production centre features a fully staffed Research and Development and Air Movement Facility. The Test Centre enables them to perform full air movement, product performance and research tests for new and existing products as well as undertake special tests or simulations to specific customer requirements.

Designed to ISO 5219 specifications, Gilbert’s Test centre has superb versatility in room arrangement which, combined with the air handling unit and ductwork set-up, allows a controlled air flow to be supplied through numerous sizes and types of device in a multitude of floor, wall and ceiling mounting positions.

DIFFUSION

Diffusion’s R+D and Test facilities combine real-world simulation, expert staff and certified test equipment which ensures that all Diffusion units will perform according to plan in their target environments. Using instruments calibrated and certified by BSRIA, Diffusion measures air volume, thermal and acoustic performance.

- Validating Air Volume Performance: Air volumes are measured on a purpose designed flow-measuring rig utilising duct mounted flow measurement equipment. The rig measures air volume, motor amps, motor power and power factor simultaneously. Units can be mounted on the rig with the project ductwork and grilles fitted to give an accurate measurement of actual site external pressure drop.

- Validating Acoustic Performance: The acoustic test lab consists of two 4mx4mx4m (64m3) reverberation chambers positioned end-to-end to allow measurements of the inlet/casing radiated and discharge levels simultaneously using full octave band sound measuring equipment.

- Validating Thermal Performance: The thermal test lab consists of a computer controlled thermal test system to accurately simulate the internal load conditions required for a given project. The system also controls the operating parameters of the unit under test with regards to water flow rates, air volume and external pressure drop. It can be used for both heating and cooling in airside and waterside control formats. Heat exchanger pressure drops can also be measured and recorded, and all results are made available as comprehensive hardcopy output.