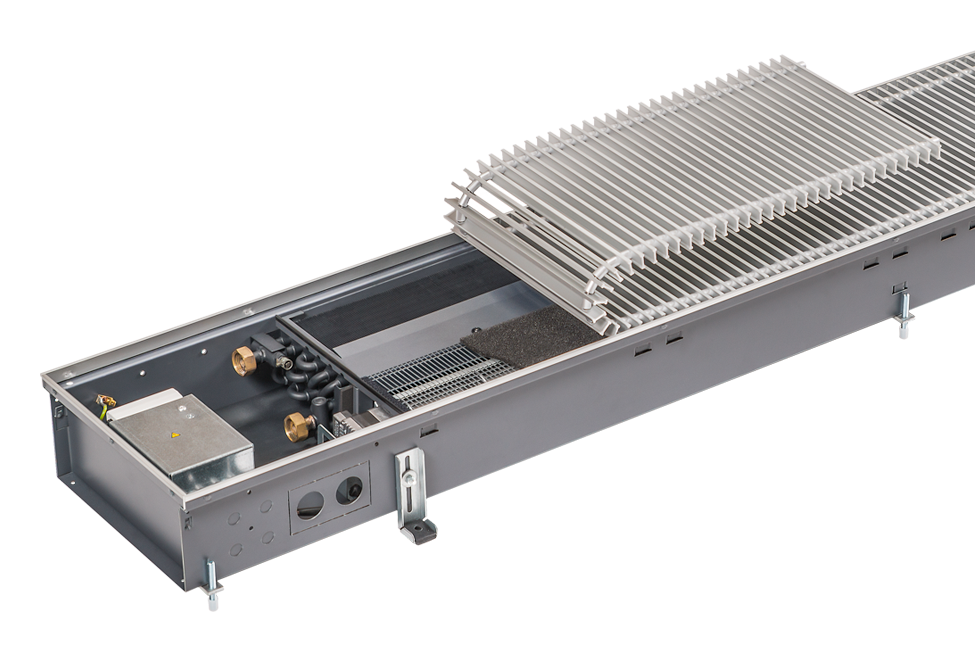

Katherm HK

Product Description

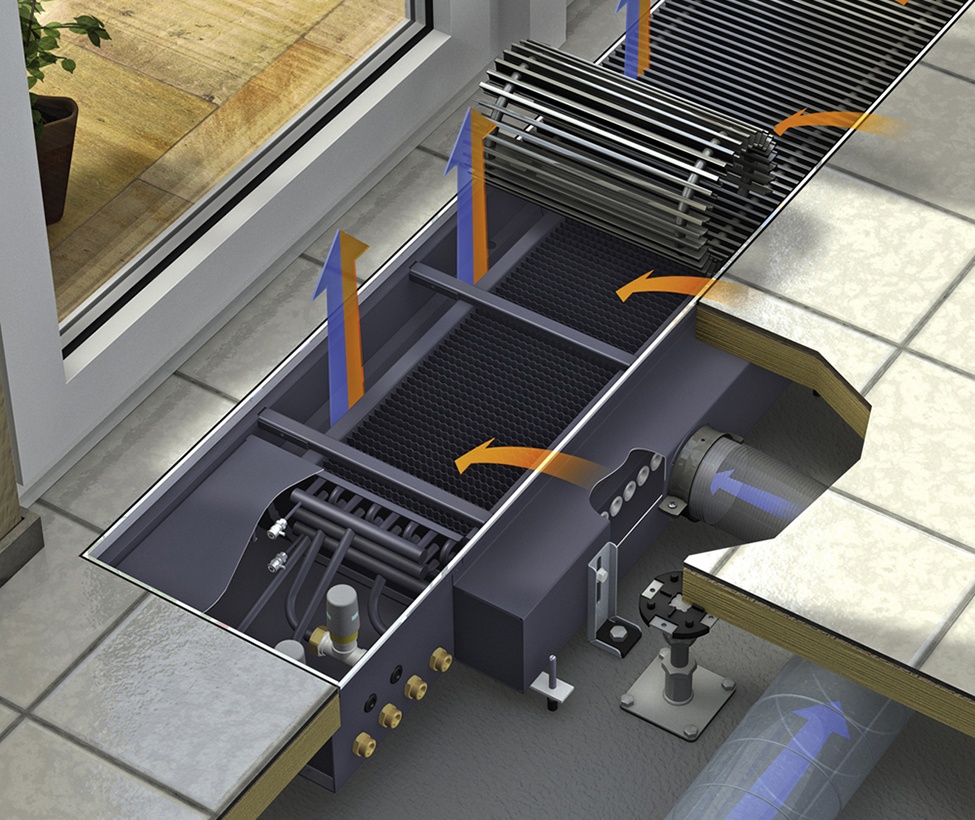

Trench heating and cooling. EC cross-flow fan convection: low-noise and energy-efficient.

Key Features

- A matching edge profile for a perfect design with every grille.

- KaControl control system as standard; can be integrated into KaControl networks or building automation system, such as KNX, Modbus or LON

- Cost-effective efficient heating and cooling even at low noise levels

Your Benefits

- Heating and cooling in a 2-pipe and 4-pipe system

- EC fan, quiet and energy-efficient

- Condensation drip tray asstandard

Technology

- Energy-saving EC tangential fan with flow-optimised impellers, cascaded arrangement as a continuous fan belt; this produces uniform airflow through convector with minimal sound emissions.

- High-performance coil optimised for airflow and heating and cooling output, with Eurokonus valve connection.

- 2-pipe or 4-pipe system for individual comfort in every room.

- Standard raised floor feet and mounting brackets with impact sound insulation for ease of installation of the trench system and avoidance of sound transfer.

- Anti-torsion mechanism for heating connections prevents damage to the convector when fitting the valves; valves optionally available as accessories.

- Specially designed condensate tray for safe removal of the condensate and simultaneous air routing; can be pulled out to the room side for ease of cleaning in line with the Hygiene Directive VDI 6022.

- Condensate pump set (optional) to drain condensate, if needed.

Areas of application/installation

- Buildings of all kinds in which there is a high cooling requirement due to the sun’s rays

- Clear view and feel good temperature in front of full-length glass façades

- Developed to meet the requirements of a modern room air conditioning

- 9unit lengths, 2 unit widths, 2 unit heights; made-to-measure lengths on request

Also good to know

- The heat outputs were measured and determined in accordance with DIN EN 16430 “Fan-assisted radiators, convectors and trench convectors” Part 1: “Technical Specifications and Requirements”, Part 2: “Test method and Evaluation of Heat Output” and Part 3 “Test Method and Evaluation of Cooling Output”.

- The acoustics measurements were carried out in a semi low-reflective acoustic chamber in compliance with DIN EN ISO 3744.